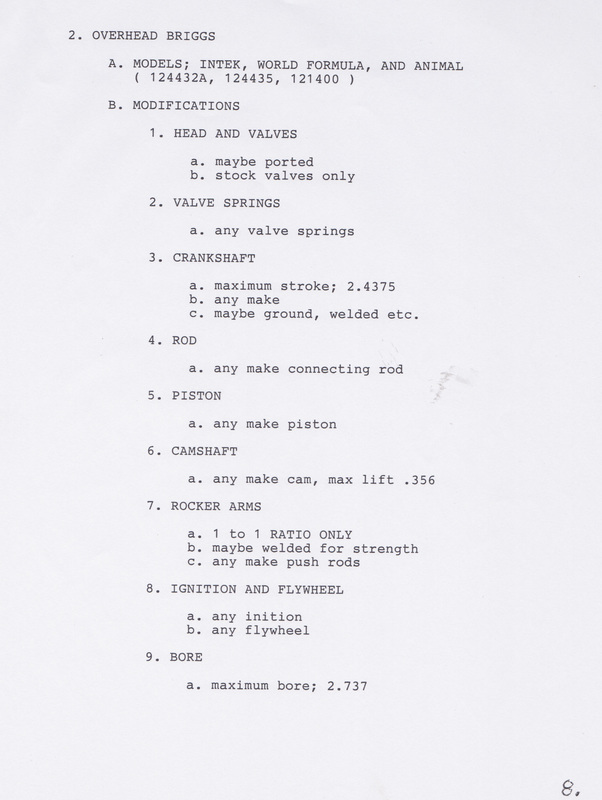

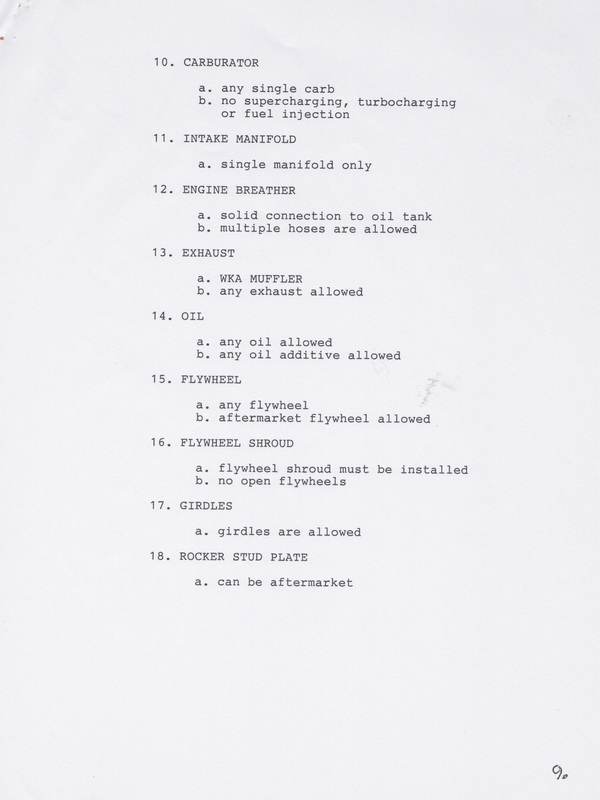

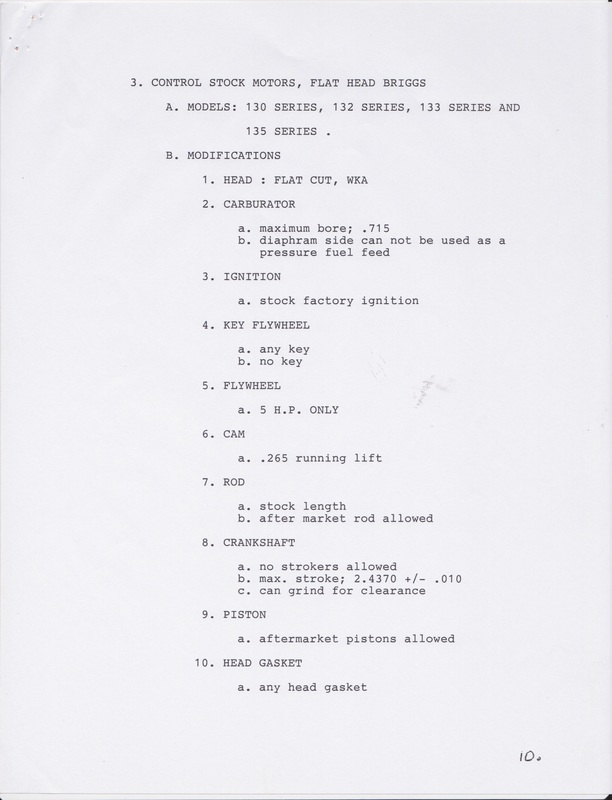

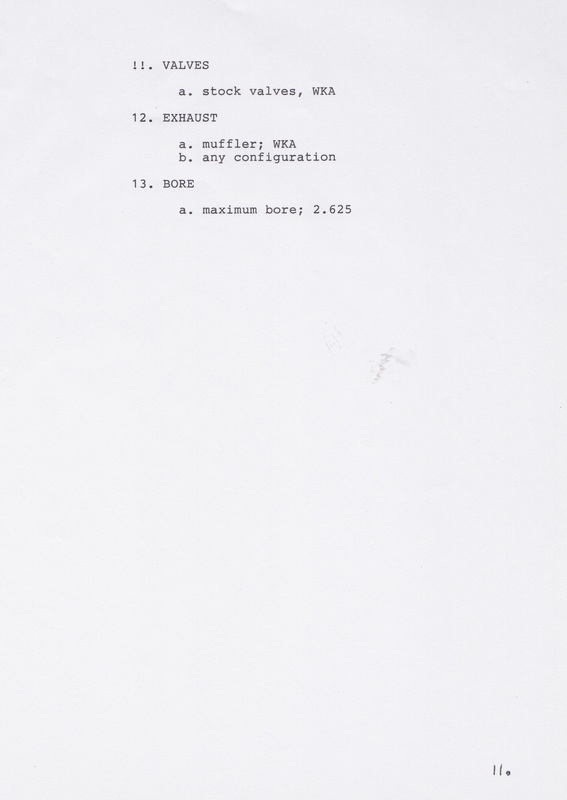

Modified Microstock Specs

by John Kazmierski & John Paulsen

| modified-microstock-specs_by_john_k_and_john_paulsen.pdf |

UPDATE: As of 3/12/2023- The weight for Modified Microstocks will be 450 Pounds. Top three finishers will need to go to the scales after each race.